The oil in your hydraulic press is the lifeblood of the equipment. Just like your car, it needs regular maintenance. Without clean oil in the proper amounts, your press won’t run right and it will have a much shorter lifespan.

Considering how expensive hydraulic presses are, the small amount of time it takes to keep your oil in good shape is a tiny, and worthwhile investment. A hydraulic press maintenance checklist is an essential for any machine shop, whether it uses H-frame press or C-frame press equipment.

The Importance of Oil

The oil in your hydraulic press circulates throughout the equipment, like the oil in your car’s engine and the blood in your body. Dirty oil causes problems for all areas of your press. If the levels are too low, your press will wear prematurely and produce a lower quality product.

A regular system of checks and maintenance will keep your press producing products for your customers steadily and reliably. The press will work more efficiently and safely.

The major enemies for the oil in your hydraulic press are dirt, contamination and heat. Each of these feeds on the other and together they can cause a significant reduction in output and years of working life, as well as increase in repairs.

Daily Inspections

Your first line of defense is a regular inspection done at the start of each workday or shift. Here is what to look for.

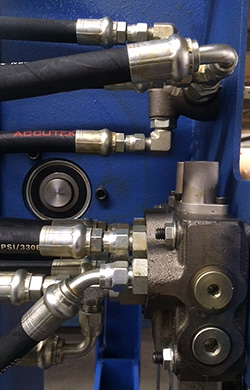

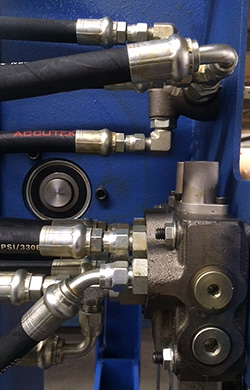

Check for leaks on the hydraulic lines. A small oil leak can be hard to detect. But left unchecked, it can rapidly turn into a major problem that takes time for cleanup and repair.

Check for tiny leaks daily. Be sure to tighten fittings that are leaking. Take care to clean off excess oil. This attracts less dirt and also gives you a cleaner su rface, which makes it easier to spot future leaks. Your machinery will also run cooler when it is cleaner.

rface, which makes it easier to spot future leaks. Your machinery will also run cooler when it is cleaner.

Also check the bolts around the tooling area. These can get loose due to vibration and shock.

Check the oil quantity. Your press needs a certain level of oil in it at all times in order to run safely and efficiently. Inspect the oil levels and top it off whenever it is low. Follow the guidelines from the manufacturer for the right type of oil to use, usually listed on an oil tag.

Check the guided platens. There are two types, one of which needs lubrication and the other which needs none or very little. Consult the press manual for the needs of your hydraulic press.

If you have bushings that require regular lubrication, make sure they maintain a thin layer over the rod. Be careful to not over-grease, which attracts dirt and leads to premature wear.

If you have bushings that have a check valve-type fitting, they probably don’t need regular lubrication because they have graphite impregnated into the bronze. If you do oil them, try an oil like Mobil Viscolite® or similar, used in very small amounts to spread graphite onto the rod. Don’t grease this type of bearing.

Check how hot the oil is. Aim for an operating temperature of 120 degrees F.

Check the ram. It should never be dripping with oil. Instead simply keep it moist.

Oil Maintenance

In order to keep your equipment running at 120 degrees F, you need to know what the temperature is at all times. This is done with a probe placed in the oil reservoir. The press thermostat keeps levels at the temperature.

Air or water coolers are used to maintain the temperature. Make sure the radiator, which is part of the system of the air cooler, is kept clean. Use an inexpensive filter, like what is used in heating and air conditioning units. This prevents clogs in radiator vanes, which can be easily get dirty, restricting the airflow and causing fluctuations in the temperature.

Sample the oil at least once a year. Check for signs of contamination and that the fluid properties are within the acceptable range specified by the manufacturer.

Regular maintenance will add years to the working life of your hydraulic press. The time spent is an investment, one that pays high dividends in customer satisfaction, fewer repairs and replacements and less downtime.

Français

Français

rface, which makes it easier to spot future leaks. Your machinery will also run cooler when it is cleaner.

rface, which makes it easier to spot future leaks. Your machinery will also run cooler when it is cleaner.